Mini Milling Machine with 5 Axis

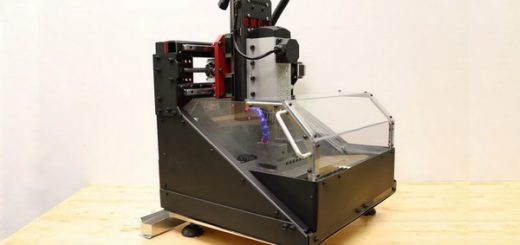

Pocket NC V2-10 is a 5-axis CNC table top milling machine, a compact tool capable of reproducing even three-dimensional objects.

When it comes to reproducing an object in 3 dimensions, the first thought goes to 3D printers, which are based on the concept of additive manufacturing process: the part is built from the base by adding a layer of molten material at a time.

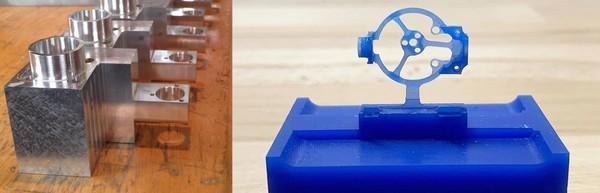

Milling instead is a subtractive process in which the material is removed from a solid using a sharp tool to reveal what will be the final piece.

CNC stands for Computer Numerical Control, which means that the machine is controlled by a series of codes and numbers issued by a computer, these codes are usually issued by a special software.

Conventional milling machines can generally move on 3 linear axes at a time, usually there is a moving part that moving on the fixed part, can move forward and backward in two directions (X and Y axes) and the cutting tool can move up and down (Z axis).

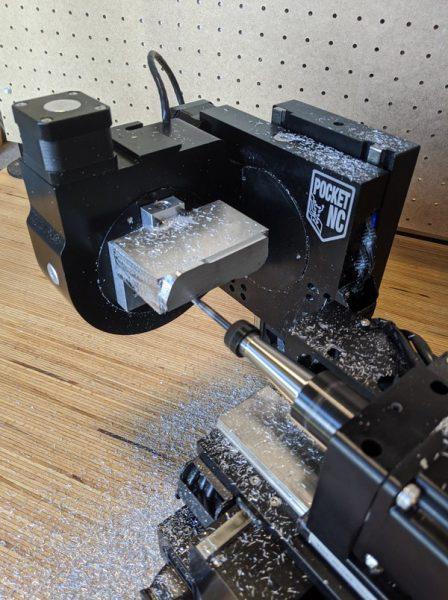

The 2 axes of extra movement are rotational, which for the Pocket NC means that the part can also rotate around the X axis (A axis) and around the Y axis (B axis); the most immediate advantage of this is that it is possible to work on multiple faces of the piece without having to reposition it.

Pocket NC V2-10 can process materials up to a hardness equal to that of titanium G5 and is able to operate optimally with delrin (plastic), aluminum or softer steels.

(Watch the video)

The stroke of the Pocket NC is 115 mm in X, 127 mm in Y and 90 mm in Z. The maximum stroke in the A axis is from -25 ° to 135° and the maximum stroke in the B axis is from -360° to 360°.

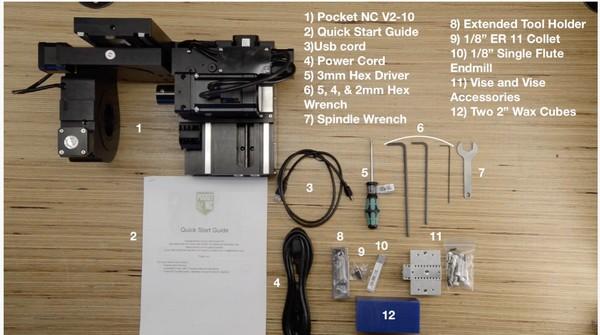

The machine accepts the standard G code, comes with a series of accessories as standard, while additional accessories are available for purchase separately.

Technical Specifications:

| Spindle Speed: | 2000-10000 g/min |

| Power: | 200 W (Max) |

| Dimension: | 444.5 mm x 279.3 mm |

| Connectivity: | Ethernet, USB e mini USB |

| Power Supply: | 90-264 VAC, 127-370 VDC, 47-63Hz |

For more information, visit the website.