Wind Turbine Without Blades

Vortex Bladeless is an alternative and innovative way to harness wind energy, with different and original features that make it a revolution in wind power generation.

It is essentially a resonant wind generator with vibration induced by vortices. It harnesses wind energy from a vorticity phenomenon called Vortex Shedding.

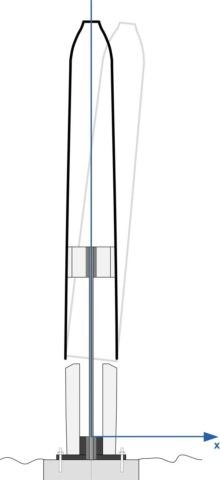

Constructively, this bladeless technology consists of a cylinder fixed vertically with an elastic rod. The cylinder subjected to the action of the wind oscillates, transmitting the movement to a generator which transforms it into electrical energy.

The design of this wind turbine is very different from a traditional turbine. Instead of the usual tower, nacelle and blades, this device only has a shaft made of lightweight materials on a rigid base.

(Watch the video .)

Vortex wind generators are more similar in characteristics and convenience over time to solar panels than to normal wind turbines.

The outer cylinder is designed to be rigid but has the ability to vibrate while remaining anchored to the lower stem. The lower part or the base is firmly anchored to the ground. The structure is made using resins reinforced with carbon fiber and / or glass, that is, materials used in conventional wind turbines.

Vortex Bladeless, captures wind energy by means of a resonance phenomenon produced by an aerodynamic effect known as vortex shedding. In fluid mechanics, when the wind passes through a blunt body, the flow is modifird and generates a cyclical pattern of vortices. Once the frequency of these forces is close enough to the body’s structural frequency, the body begins to oscillate and resonates with the wind. This is also known as Vortex Induced Vibration (VIV).

This VIV phenomenon is commonly avoided in structural engineering, aeronautics and architecture. Vortex turbines, on the other hand, maximize these aerodynamic instabilities and wind turbulences by capturing their energy.

Vortex shaft geometry is specially designed to achieve maximum performance at average recorded wind speeds. It is able to quickly adapt to changes in wind direction and turbulent air flows.

Normal wind turbines must be installed away from each other due to the disturbance of the wind current downstream of each. For turbines without blades, this problem does not exist, in fact there are no problems related to the “wake effect”.

Vortex generates electricity through a system of alternators, consisting of coils and magnets, adapted to the dynamics of the vortex, without gears, shafts or rotating parts. While alternators are a well-known technology, the way Vortex uses them is innovative and patented. It is a system that reduces maintenance and eliminates the need for lubrication.

The Vortex oscillating shaft has been designed so that it can adjust its vibration resistance (rigidity) which allows it to adapt and make the most of a wide range of wind conditions.

Current wind turbine technology has to support very different load levels at variable wind speeds, which places high mechanical demands on transmission components such as gears, bearings, bushings or brakes. The multiple moving parts are constantly subjected to wear, which leads to high maintenance costs.

The blade-free wind turbine completely eliminate the mechanical elements that can be worn out by friction. The main materials used for the production of Vortex turbines are carbon fiber polymers, plastic, steel, neodymium and copper. The working limits of these materials are far from Vortex operating standards.

Of course, this wind turbine is not immune to fatigue and stress forces. But targeted studies and tests have shown the longevity of this type of technology.

Thanks to the extreme lightness and close-to-ground centre of gravity, the anchoring or foundation requirements have been significantly reduced compared to normal turbines, making installation easier.

In general, Vortex wind power is less energy efficient than ordinary horizontal axis wind turbines. But on the other hand, the smaller space required allows more turbine blade-less to be installed in the same surface, compensating for energy efficiency with space efficiency in a cheaper way.

Conventional wind turbines need an orientation system to face the wind in the right direction. Vortex wind generators do not need this thanks to their circular cross section.

Vortex bladeless is primarily a solution for distributed power generation. It is perfect to be placed near a house or above the roof. It can operate on-grid and off-grid and as part of a hybrid installation solar plus wind.

For more information, visit the website.